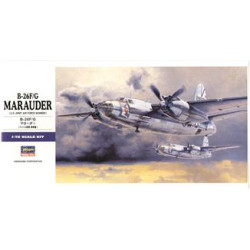

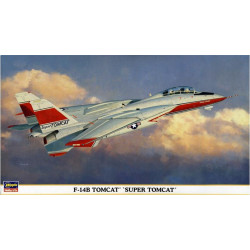

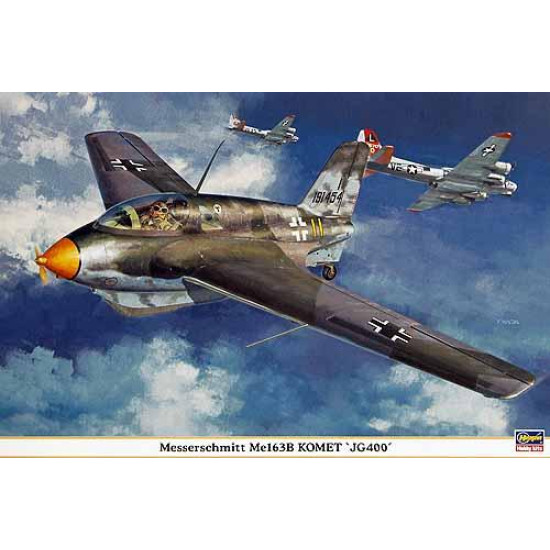

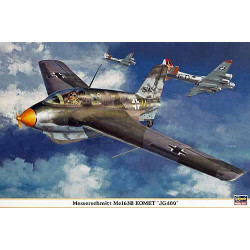

Messerschmitt Me 163 Komet

1/32 Aircrafts, Planes

Hasegawa 08177

Manufacturer: Hasegawa

Scale: 1/32

Material: Plastic

Paint: Unpainted, Unassembled, Kit do not contain paints and glue.

Condition: New in Box

The Messerschmitt Me 163 Komet, designed by Alexander Lippisch, was a German rocket-powered fighter aircraft. It is the only rocket-powered fighter aircraft ever to have been operational. Its design was revolutionary, and the Me 163 was capable of performance unrivaled at the time. German test pilot Heini Dittmar in early July 1944 reached 1,130 km/h (700 mph), not broken in terms of absolute speed until November 1947. Over 300 aircraft were built however, the Kometproved ineffective as a fighter, having been responsible for the destruction of only about nine Allied aircraft (16 air victories for 10 losses, according to other sources).Work on the design started under the aegis of the Deutsche Forschungsanstalt für Segelflug (DFS)—the German Institute for the Study of sailplane flight. Their first design was a conversion of the earlier Lippisch Delta IV known as the DFS 39 and used purely as a glider testbed of the airframe.

A larger follow-on version with a small propeller engine started as the DFS 194. This version used wingtip-mounted rudders, which Lippisch felt would cause problems at high speed. He later redesigned them to be mounted on a conventional vertical stabilizer at the rear of the aircraft. The design included a number of features from its glider heritage, notably a skid used for landings, which could be retracted into the aircraft's keel in flight. For takeoff, a pair of wheels, each mounted onto the ends of a specially designed cross axle, together comprising a takeoff "dolly" mounted under the landing skid, were needed due to the weight of the fuel, but these were released shortly after takeoff. It was planned to move to the Walter R-1-203 cold engine of 400 kg (880 lb) thrust when available, which used a monopropellant consisting of stabilized HTP known by the name T-Stoff.

Heinkel had also been working with Hellmuth Walter on his rocket engines, mounting them in the He 112 for testing, and later in the first purpose-designed rocket aircraft, the He 176. Heinkel had also been selected to produce the fuselage for the DFS 194 when it entered production, as it was felt that the highly volatile fuel would be too dangerous in a wooden fuselage, with which it could react. Work continued under the code name Projekt X.

However the division of work between DFS and Heinkel led to problems, notably that DFS seemed incapable of building even a prototype fuselage. Lippisch eventually requested to leave DFS and join Messerschmitt instead. On 2 January 1939, he moved along with his team and the partially completed DFS 194 to the Messerschmitt works at Augsburg.

The delays caused by this move allowed the engine development to "catch up". Once at Messerschmitt, the decision was made to skip over the propeller-powered version and move directly to rocket power. The airframe was completed in Augsburg and shipped to Peenemünde West, one of the quartet of Erprobungsstelle-designated military aviation test facilities of the Reich, in early 1940 to receive its engine. Although the engine proved to be extremely unreliable, the aircraft had excellent performance, reaching a speed of 342 mph (550 km/h) in one test.

A simplified construction format for the Me 163 fighter's airframe was deemed necessary, as the Me 163A version was not truly optimized for large-scale production, with design work starting in December 1941. The result was the Me 163B subtype, which had the desired, more mass-producible fuselage, wing panel, retractable landing skid and tailwheel designs with the previously mentioned unsprung "dolly" takeoff gear, and a generally one-piece nose for the forward fuselage which could incorporate a pioneering example of a "windmill" generator at the extreme front for supplementary electrical power while in flight, as well as a one-piece, perimeter frame-only hinged canopyfor ease of production.The fuel system was particularly troublesome, as leaks incurred during hard landings easily caused fires and explosions. Metal fuel lines and fittings, which failed in unpredictable ways, were used as this was the best technology available. Both fuel and oxidizer were toxic and required extreme care when loading in the aircraft, yet there were occasions when Kometsexploded on the tarmac from the propellants' hypergolic nature. Both propellants were clear fluids, with different tanker trucks used for delivering each propellant to a particular Komet aircraft, one at a time, with one truck - usually the one delivering the C-Stoff hydrazine/methanol-base fuel - leaving the immediate area of the aircraft following its delivery and capping off of the Komet's fuel tanks from a rear located dorsal fuselage filling point just ahead of the Komet's vertical stabilizer, before the other truck - most often an Opel Blitz tanker truck, of a special Ausführung S model[16] carrying the very reactive T-Stoff hydrogen peroxide oxidizer would come anywhere near to deliver its oxidizer load to the fighter for safety reasons, through a different filling point on the Komet's dorsal fuselage surface, located not far behind the rear edge of the canopy. The corrosive nature of the liquids, especially for the T-Stoff oxidizer, required special protective gear for the pilots. To help prevent explosions, the Walter rocket engine and the Komet's propellant storage and delivery systems were frequently and thoroughly hosed down and flushed with water run through both the fuel and oxidizer tanks and rocket engine's propellant systems before and after flights, to clean out any remnants of the hypergolic fuel and oxidizer.[17] The relative "closeness" to the pilot of some 120 litres (31.7 US gal) of the chemically active T-Stoff oxidizer, split between two auxiliary oxidizer tanks of equal volume to either side within the lower flanks of the cockpit area — besides the main oxidizer tank of some 1,040 litre (275 US gal) volume just behind the cockpit's rear wall, could present a serious or even fatal hazard to a pilot in a fuel-caused mishap with the Me 163B.

Me 163 Komet

Me 163 B-1a at the National Museum of Flight in Scotland

Role

Interceptor

Manufacturer

Messerschmitt

First flight

Me 163A V4 in 1 September 1941

Introduction

1944

Primary user

Luftwaffe

| General Product Info | |

| Material | NOT SET |

| Scale | 1/32 |

| Type | NOT SET |

We have the lowest worldwide shipping. And it's totally simple.

EUROPE, USA, CANADA TURKEY, ISRAEL, EGYPT, UE CHINA, JAPAN, HK, S.KOREA | AU NZ MX South America, Asia | |

| Order weight up to 0.22kg or 0.48lb | US$ 8.90 | US$ 8.90 |

| Order weight up to 0.44kg or 0.97lb | US$ 13.95 | US$ 17.90 |

| Order weight over 0.44kg or 0.97lb | US$ 19.99 | US$ 29.99 |

| Order total over $150 | FREE | PROMO US$ 19.99 |

Shipping to some countries not qualifies for the free shipping option but costs not over $29.99 for any sized order. Sorry for that, your location is too far.

- Stock: Out Of Stock

- Model: HA08177

- Weight: 0.59lb

- DATE ADDED: 08/04/2014

-250x250w.jpg)